AUTOMATE YOUR PRODUCTION PROCESSES

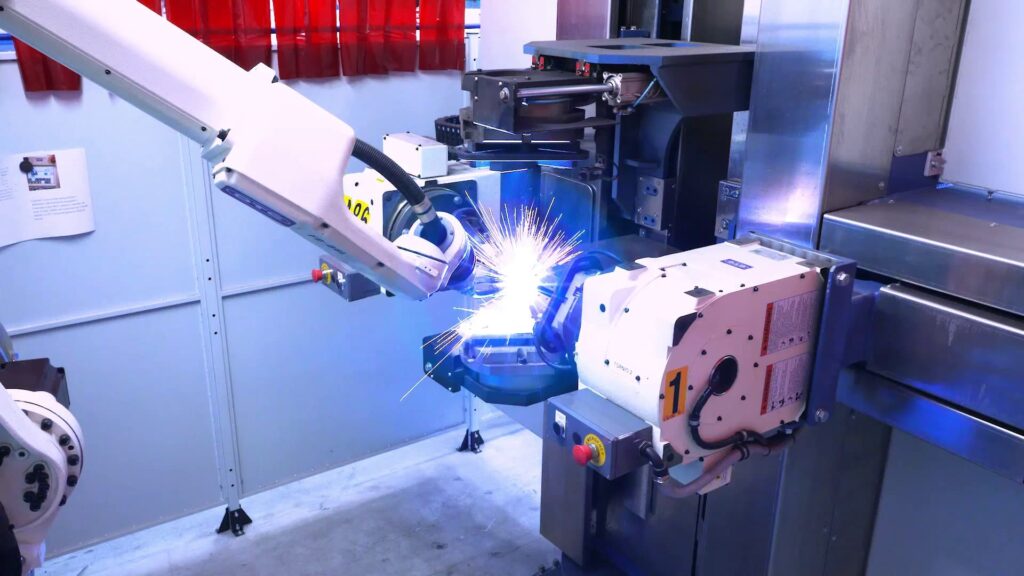

Reduce errors and rework: switch to robotic welding.

Robotic Welding: Continuous Power, Zero Compromises

Reliable, precise, and consistent: robotic welding enables standardized quality, minimized

downtime and increased efficiency across all production shifts.

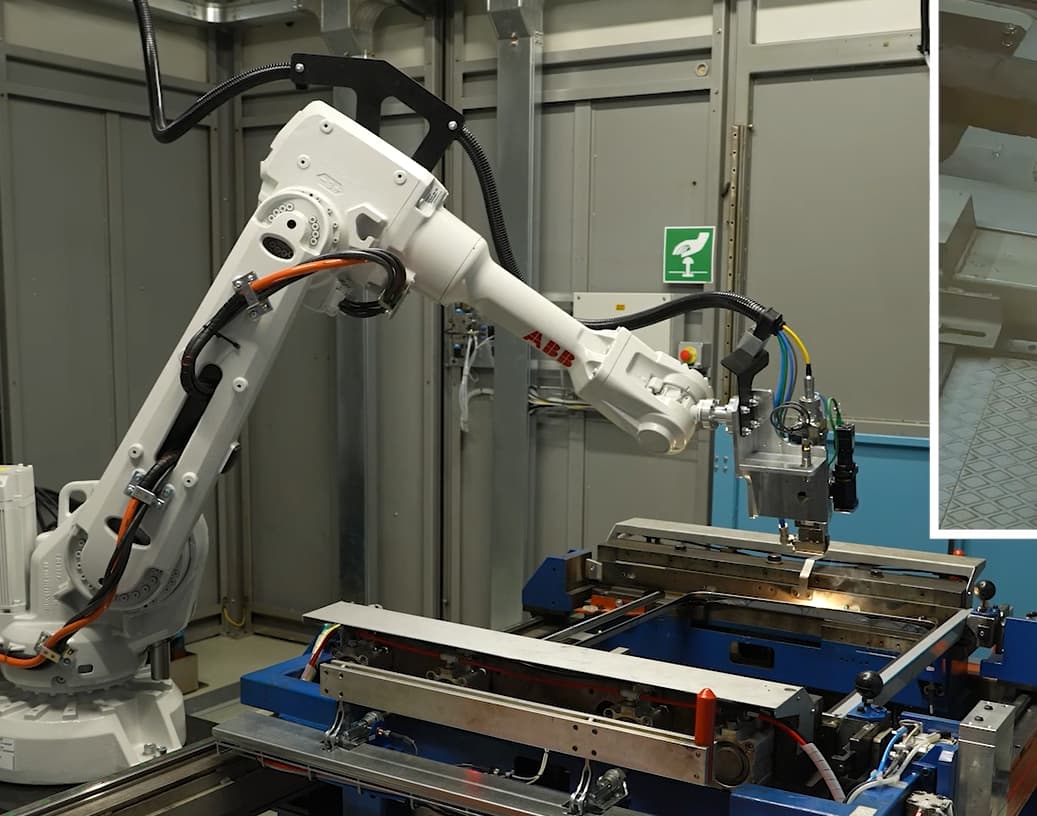

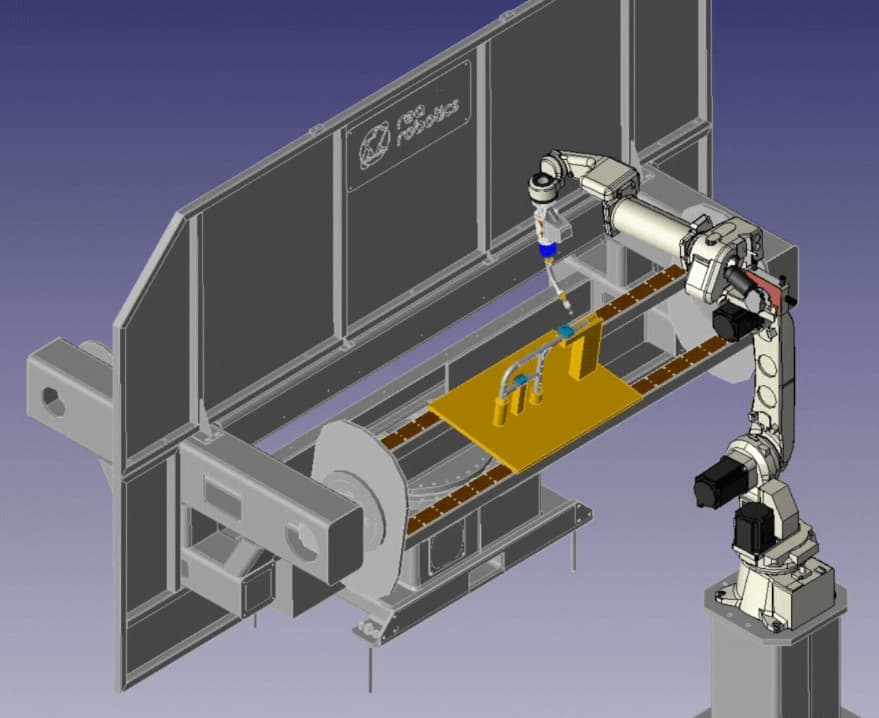

It’s a technology we know in depth, it’s where our journey began. For 40 years, we’ve been

designing robotic welding cells that are built for easy integration, long-term durability and

scale with your production needs.

Explore REA Robotics Robotic Welding Cells

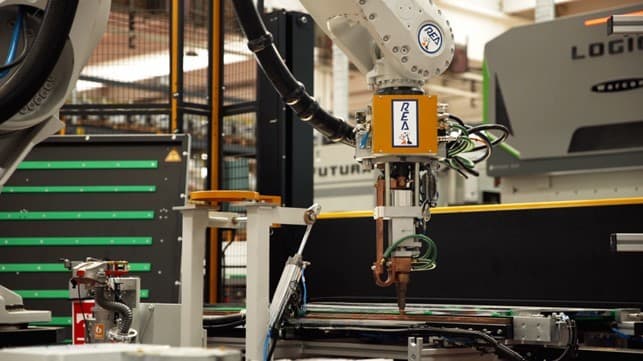

MORE CONTROL, LESS VARIABILITY.

Robotic Welding: Measurable Advantages.

Managing minimal tolerances, maintaining quality on variable batch sizes and

overcoming the limitations of manual labor: automation delivers repeatability,

scalability, and real-time monitoring. Integrating robotic cell optimizes every stage of the

process, ensuring consistent quality, full parameter traceability and operational continuity,

even with complex geometries or fluctuating production volumes.

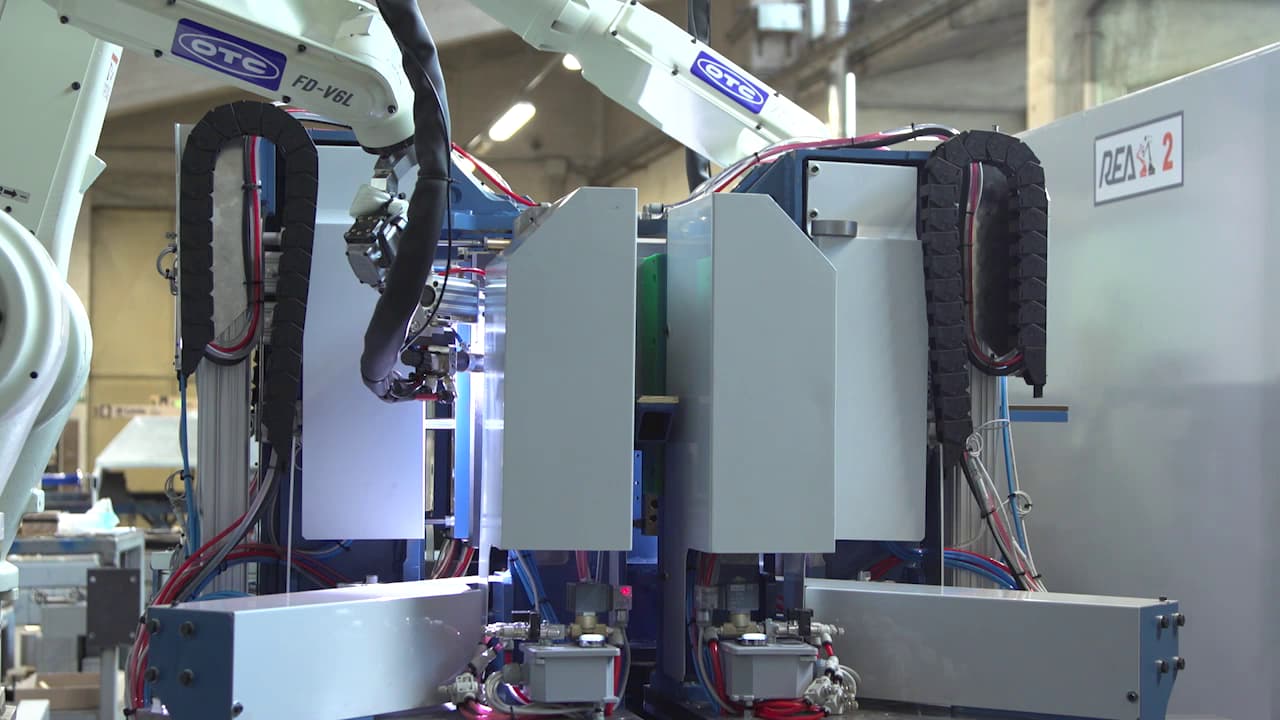

DIFFERENT TECHNIQUES, ONE GOAL: BETTER WELDING

Technologies Behind High-Quality Automated Welding

We integrate a wide range of welding technologies into our systems, choosing the best

solution for each application based on weld quality, mechanical strength, visual

finish and execution speed. With over 40 years of experience, we deliver robotic cells

ready to handle complex processes with maximum reliability.

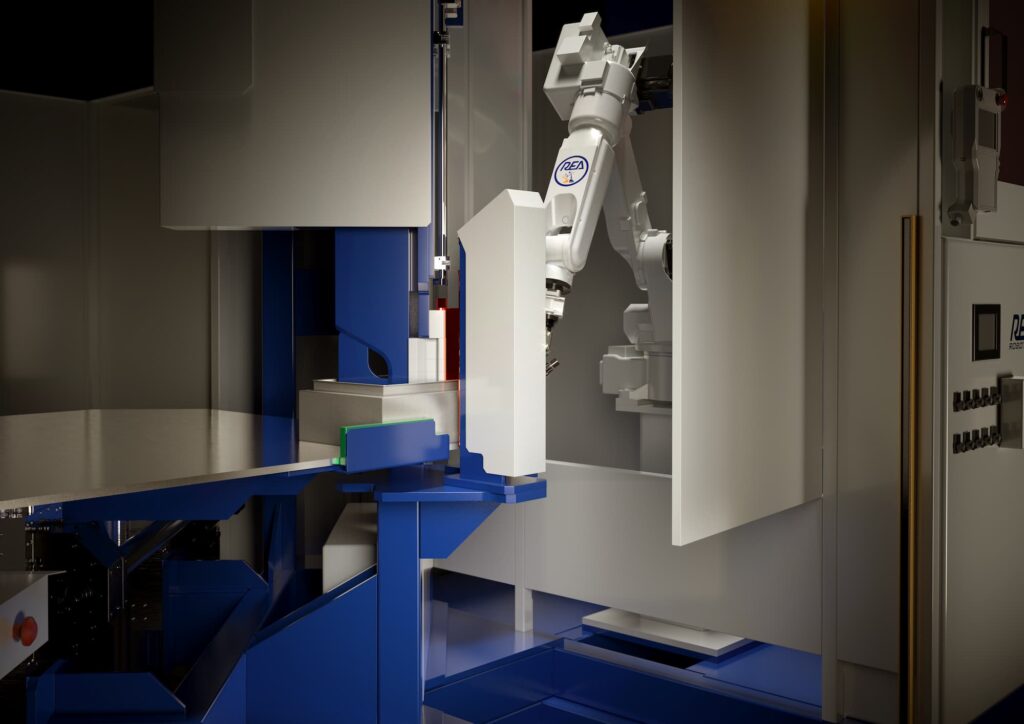

FROM THIN SHEET METAL TO HEAVY CARPENTRY

Robotic Welding Applications and Materials

Our robotic welding cells go beyond welding: they manage complex tasks like bending,

handling and integration into FMS (Flexible Manufacturing Systems) for the

production of cylinders, hoods, ovens, boxes and electrical panels, agricultural machinery,

aerial platforms and many other applications where precision and reliability are critical.

Case study

CONTACT US

Your Ideal Welding Solution:

Reliable Standard or Custom-Tailored?

Fill out the form and one of our experts will contact you to evaluate your application.