A STRATEGIC INVESTMENT

Optimize your production process. Switch to robotic bending.

Automate, accelerate, improve.

With REA Robotics’ modular solutions, you can turn your press brake into an advanced

efficiency hub: zero errors, consistent rhythm, replicable results.

Intuitive interface, immediate impact – easily integrable into existing production cells

and lines.

Discover our solutions for robotic bending

A STRATEGIC INVESTMENT

Robotic bending: measurable benefits for every production line

Choosing robotic bending is not just a technological upgrade – it’s a new approach to

manufacturing. It transforms a critical production point into a strategic asset, eliminating

inefficiencies and ensuring operational continuity, consistent precision, and scalable output.

REA Robotics’ solutions automate repetitive tasks, reduce physical strain, and free up

valuable human resources for higher-value operations. A new human-machine synergy,

designed to make a difference.

By automating repetitive tasks, you can reduce physical strain and free up valuable resources for higher-value activities. A new human-machine synergy, designed to truly make a difference.

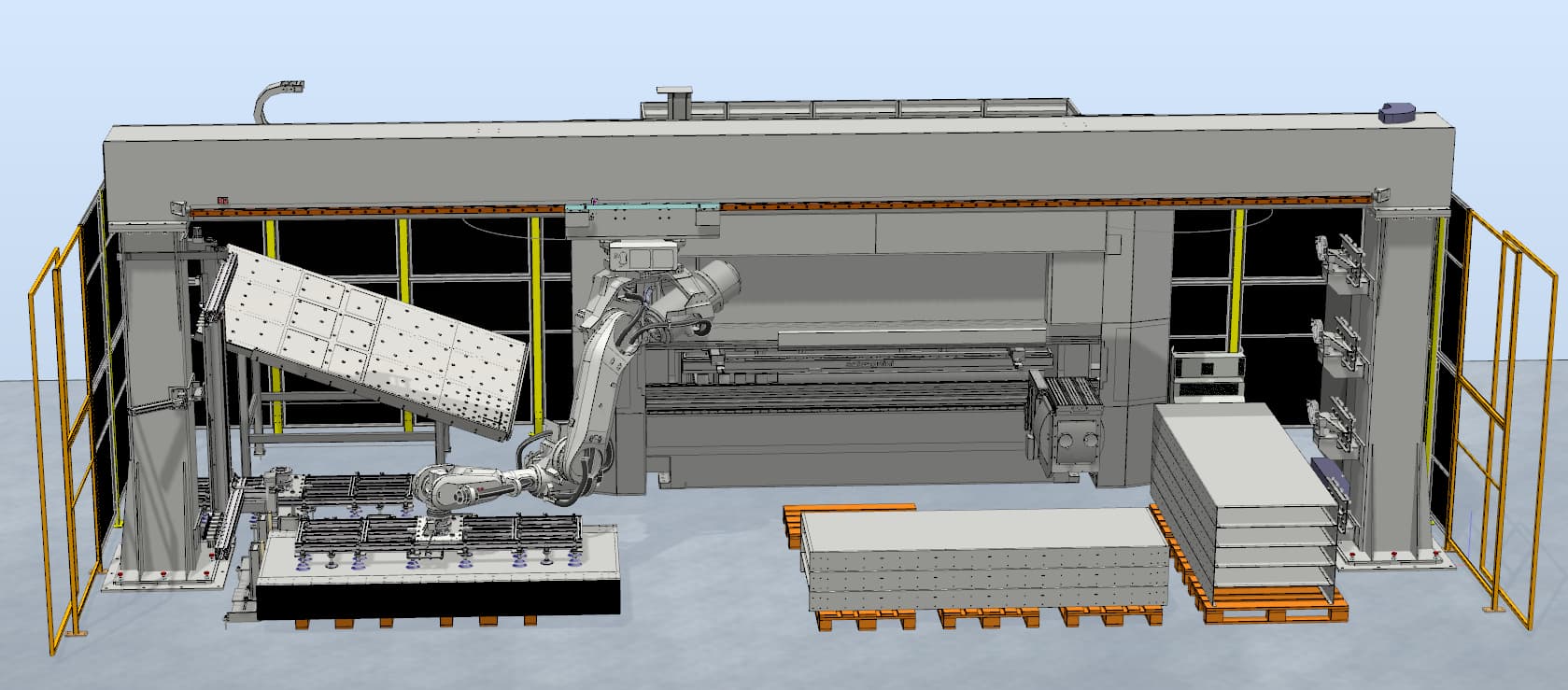

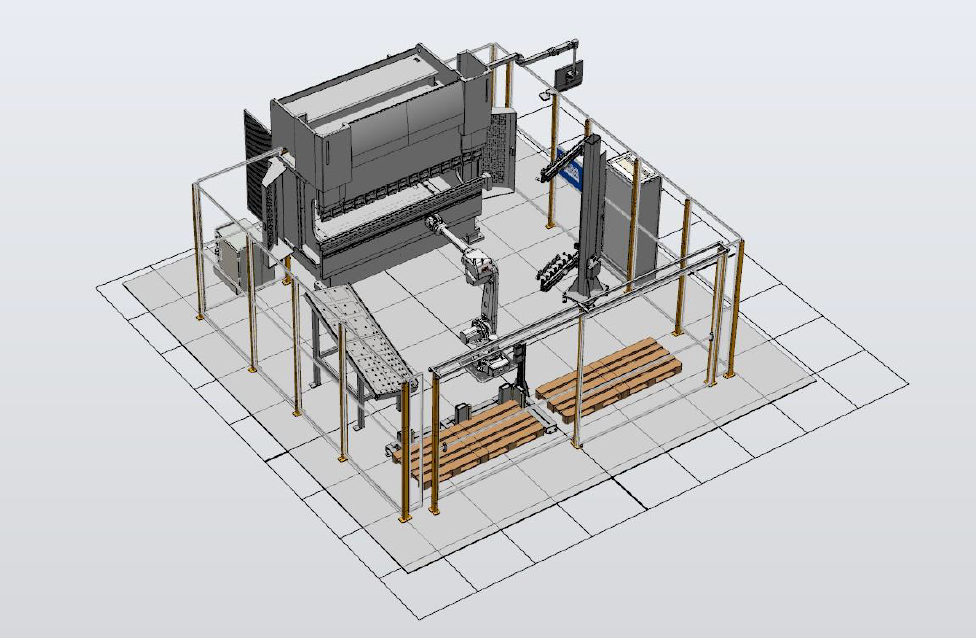

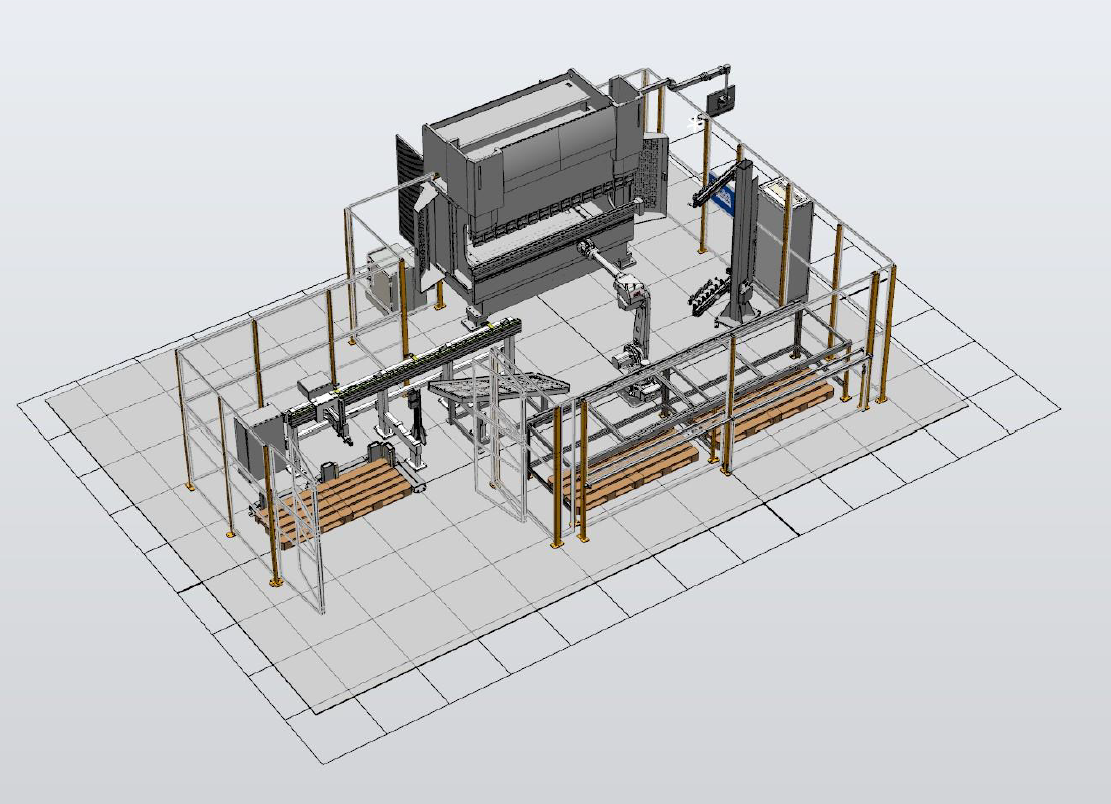

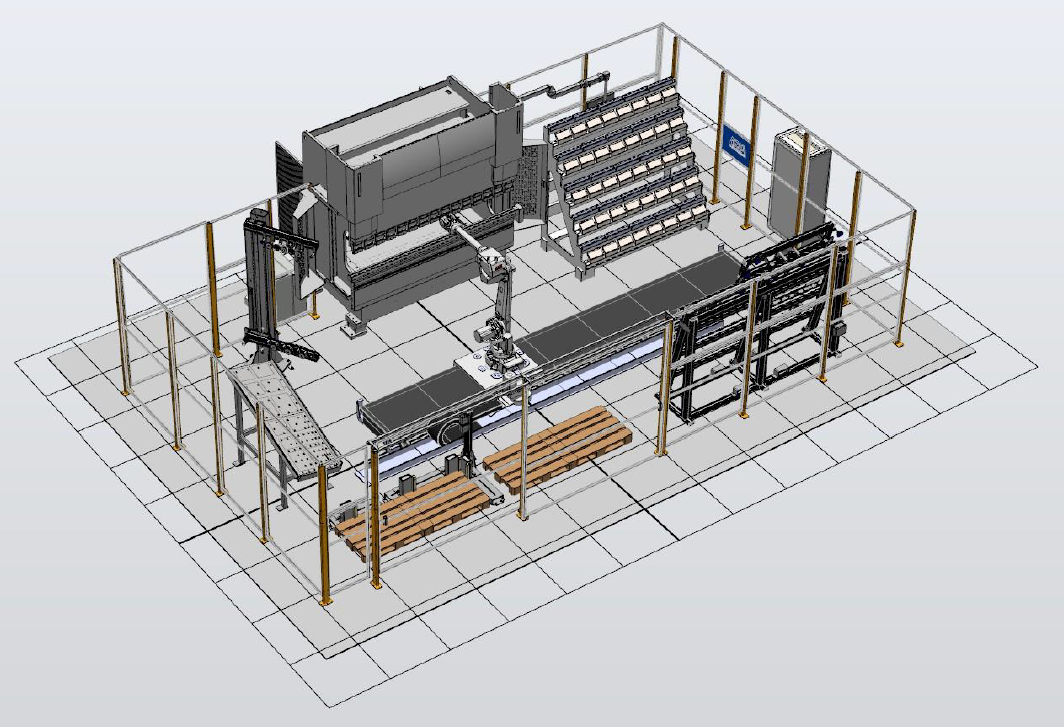

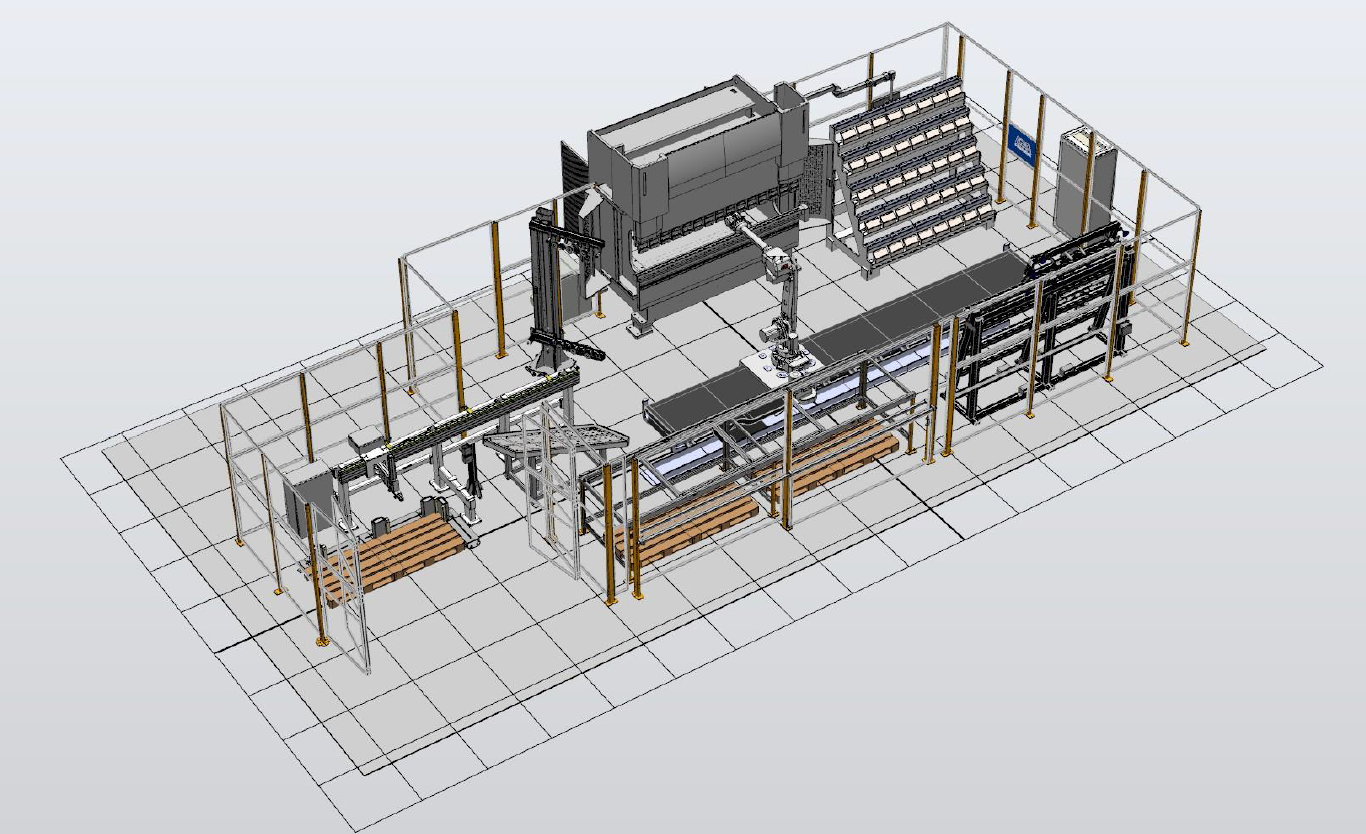

ONE CELL, INFINITE SOLUTIONS.

Discover the BendAptive cell line

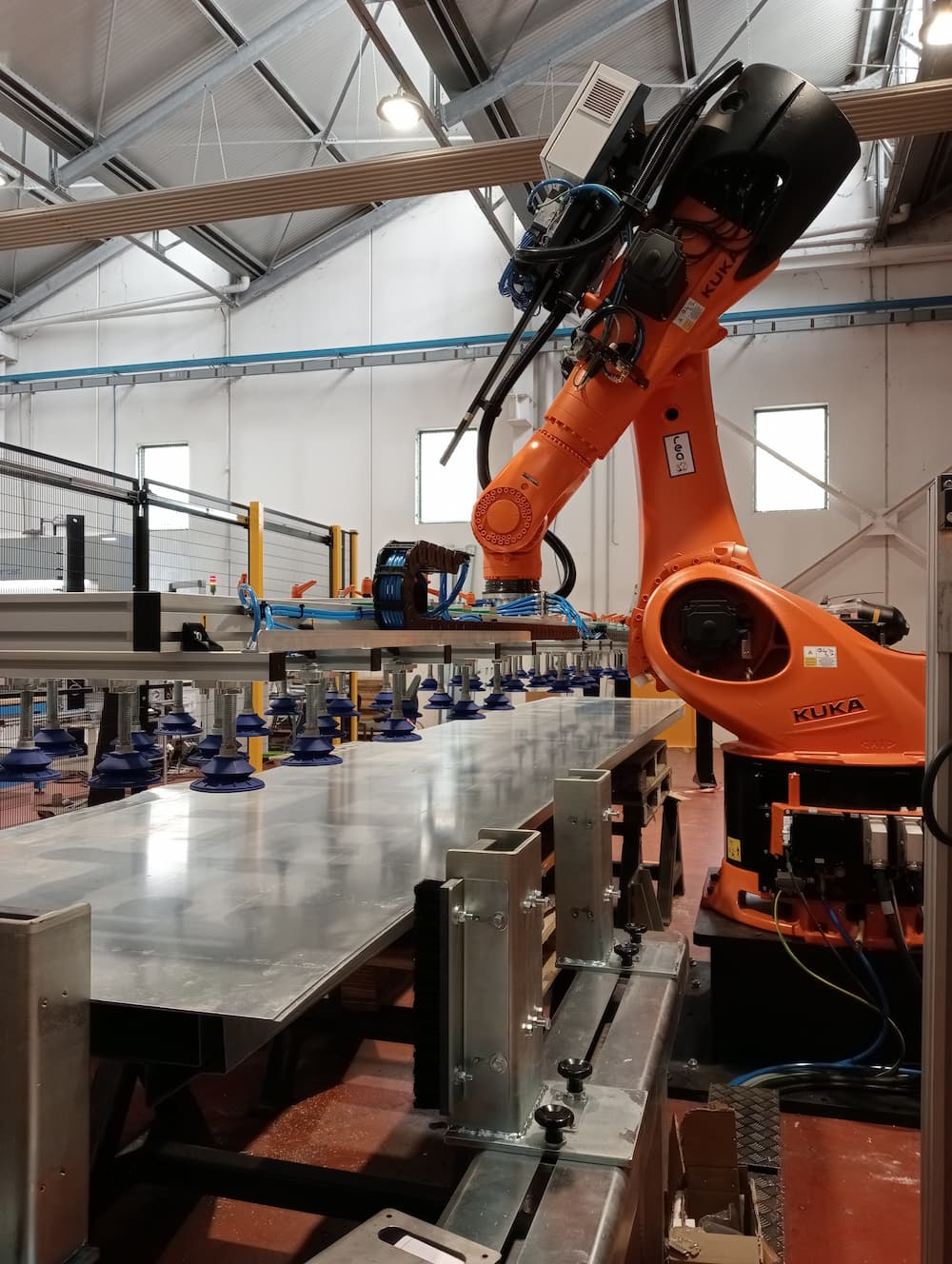

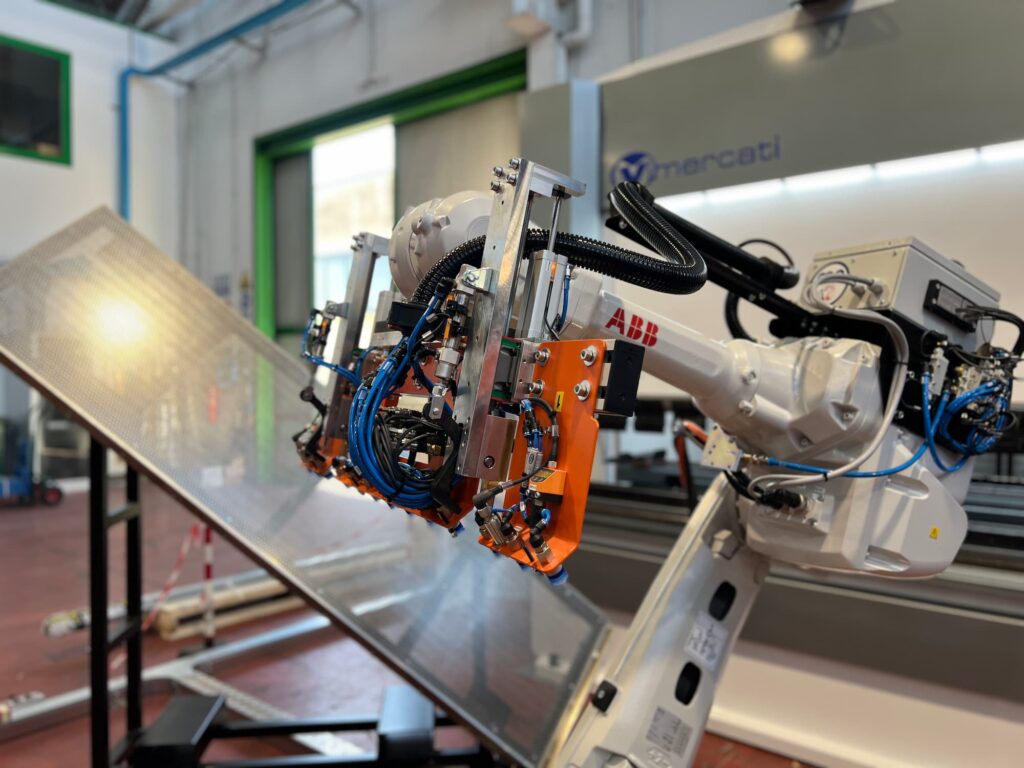

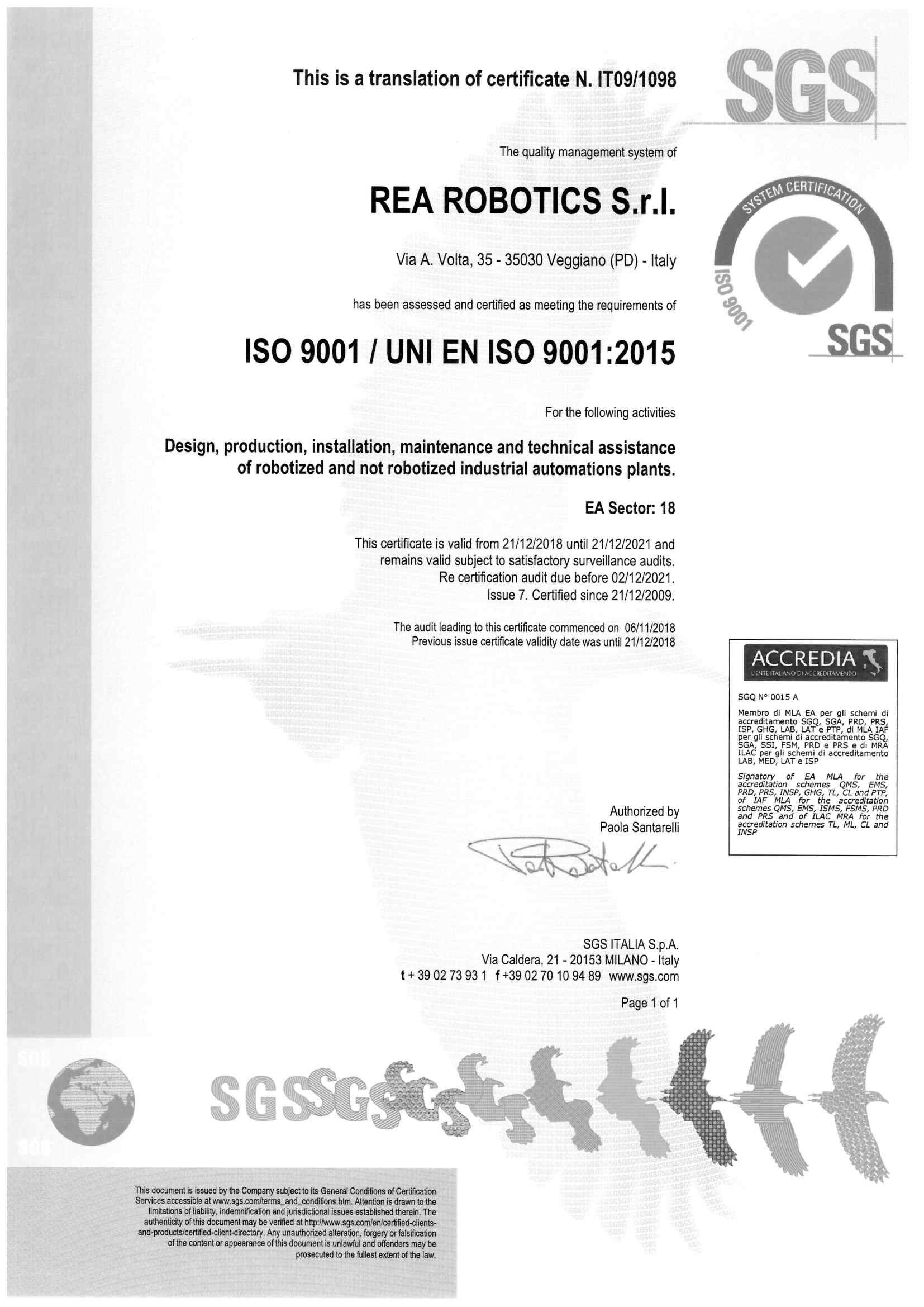

With over 40 years of experience in industrial automation, REA Robotics has developed dedicated robotic solutions for sheet metal bending.

The BendAptive line is designed to deliver modular systems addressing two key needs:

Tailored Flexibility: With integrable modules, press dimensions can be adapted to various sheet metal types, considering both production requirements and technical constraints.

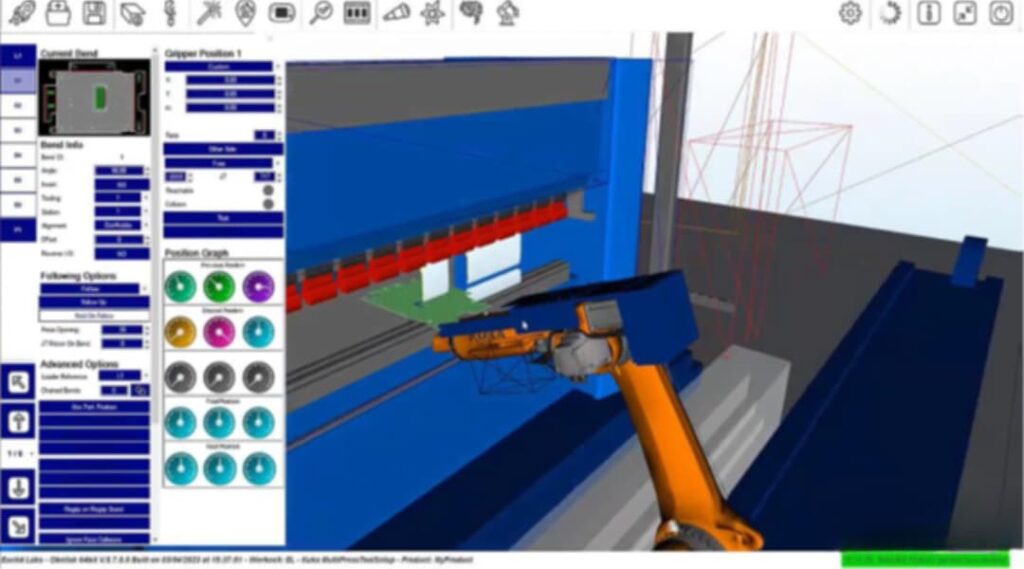

Simplicity & Performance: The system ensures precision and productivity without complexity, featuring an intuitive interface and dedicated offline programming software, facilitating communication between the robot and the press

Available standard configurations:

CASE STUDY

CONTACT US

Robotic bending: the next move is yours.

Fill out the form: one of our specialists will analyze your layout, materials, and production volumes to identify the most suitable robotic solution.

No pre-packaged solutions – just integrations designed to truly work.